Sustainability is no longer just a choice—it’s a necessity for industries aiming to mitigate environmental impact. For oil pump manufacturers, the shift toward greener processes is especially critical. By adopting innovative practices, gear oil pumps can be designed and produced with reduced environmental impact, paving the way for both efficiency and responsibility in the industry.

This blog explores sustainable practices in oil pump manufacturing, their impact on the environment, and how they meet shared global goals for eco-consciousness. We’ll also highlight key advancements made by forward-thinking organizations prioritizing green initiatives.

Why Sustainability Matters in Oil Pump Manufacturing

Manufacturing processes, including those for gear oil pumps, often have a significant environmental footprint. From material sourcing to energy consumption, each step can contribute to greenhouse gas emissions, resource depletion, and waste.

With global regulations tightening, stakeholders in the oil pump industry are under increasing pressure to adopt sustainable strategies. These green practices not only reduce the industry’s footprint but also align with the values of eco-conscious clients and partners.

Key environmental concerns include:

- High energy use during manufacturing processes

- Excess waste generation and inefficient material use

- The carbon footprint linked to global logistics and supply chains

- Challenges in recycling used or damaged oil pumps

However, innovative manufacturers are addressing these challenges head-on through sustainable engineering, ethical sourcing, and energy efficiency in factory operations.

Green Practices Leading the Way

1. Eco-Friendly Material Sourcing

Using recycled or sustainable materials in the production of gear oil pumps significantly reduces waste. Many manufacturers source steel or aluminum alloys derived from recycling, which keeps production efficient while lessening the demand for virgin resources.

Additionally, some manufacturers now look for biodegradable or recyclable lubricants in their pumps. Sustainable material options make pumps not only greener but also more cost-effective for clients over time, thanks to reduced disposal costs.

2. Energy-Efficient Manufacturing

Reducing energy consumption during manufacturing is one of the most effective ways to shrink an environmental footprint. Manufacturers can accomplish this by implementing better energy systems in their factories.

Examples include:

- Installing renewable energy sources, like solar panels or wind turbines, to power their facilities.

- Upgrading outdated machinery to energy-efficient alternatives.

- Employing heat recovery systems to minimize waste energy.

By focusing on efficiency, oil pump manufacturers save costs while reducing pollution. Clients benefit from lower manufacturing premiums and environmentally friendly sourcing options.

3. Designing for Durability and Efficiency

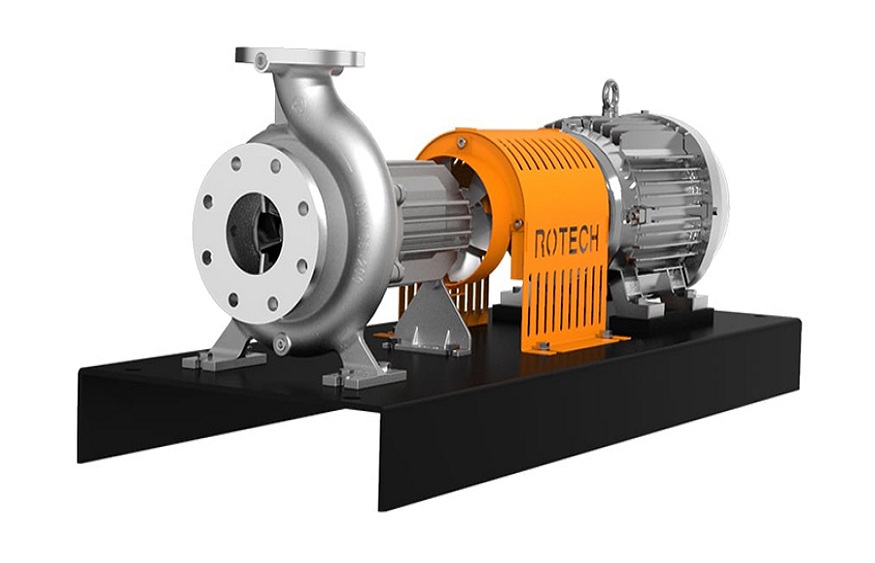

Gear oil pumps are being redesigned for maximum durability, decreasing the need for frequent replacements. By producing pumps with longer lifespans and higher energy efficiency, manufacturers help reduce long-term resource use.

For instance, modern oil pumps are now being designed with advanced sealing technologies to minimize leaks and reduce oil waste. Similarly, energy-efficient motors within these designs reduce power consumption, leading to financial and environmental savings for users.

4. Waste Management Innovations

Waste reduction is fundamental in green manufacturing. Companies are adopting closed-loop recycling systems, which allow them to reuse metal shavings, waste oils, and other by-products from the production line.

Some leaders in the gear oil pump industry also partner with recycling companies, ensuring that end-of-life products are properly disassembled and recycled to offset waste.

Pro Tip: Manufacturers committed to environmental excellence often provide customers with clear guidelines for environmentally safe disposal or recycling procedures for their products.

5. Localizing Supply Chains

Shipping components and products across the globe generate significant carbon emissions. By localizing supply chains, oil pump manufacturers can drastically cut down on transportation-related pollution.

Choosing nearby suppliers also supports local communities and limits risks associated with long-distance logistics, such as delays and excess costs. It’s a win-win strategy for both businesses and the environment.

How These Green Practices Impact the Industry

The shift toward sustainable practices within gear oil pump manufacturing has far-reaching benefits, including reduced environmental harm and a stronger brand reputation. Additionally, implementing these practices often results in cost savings and operational efficiencies over time.

Eco-conscious buyers, including businesses and partners, are demanding greener products and practices from their suppliers. By leading on sustainability, manufacturers position themselves for long-term growth and relevance in an environmentally conscious market.

Regulatory Alignment:

Governments and international bodies are rolling out strict mandates for sustainable manufacturing. By addressing these evolving requirements now, oil pump manufacturers can ensure compliance and avoid potential penalties.

Customer Benefits:

Eco-friendly manufacturing results in better performance, longer product lifespans, and reduced operational expenses for end users. This not only meets environmental goals but delivers tangible value to the businesses and individuals using these gear oil pumps.

The Future of Sustainable Manufacturing

The oil pump manufacturing industry has made great strides—but there’s more work ahead. Future advancements might focus on next-generation materials, AI-integrated manufacturing processes for energy conservation, or entirely renewable systems for powering production lines.

By continuing to innovate, manufacturers can stay at the forefront of sustainability while improving the efficiency and performance of their products. These advancements will elevate industry standards and help address the ongoing challenges of climate change.

Taking the Lead on Green Manufacturing

Sustainability in gear oil pump manufacturing is no longer optional; it’s essential. By incorporating sustainable practices such as eco-friendly sourcing, energy-efficient production, durable design, effective waste management, and localized supply chains, manufacturers are paving the way to a greener future.

Whether your business is seeking solutions aligned with environmental values or striving to meet evolving regulations, working with manufacturers that prioritize eco-conscious strategies is the best choice.